HDPE is one of the most popular materials used in manufacturing today. It is used to make many different types of products in its pure form, and is often recycled to make a composite material for manufacturing as well. So what is HDPE and why is it so advantageous to our future?

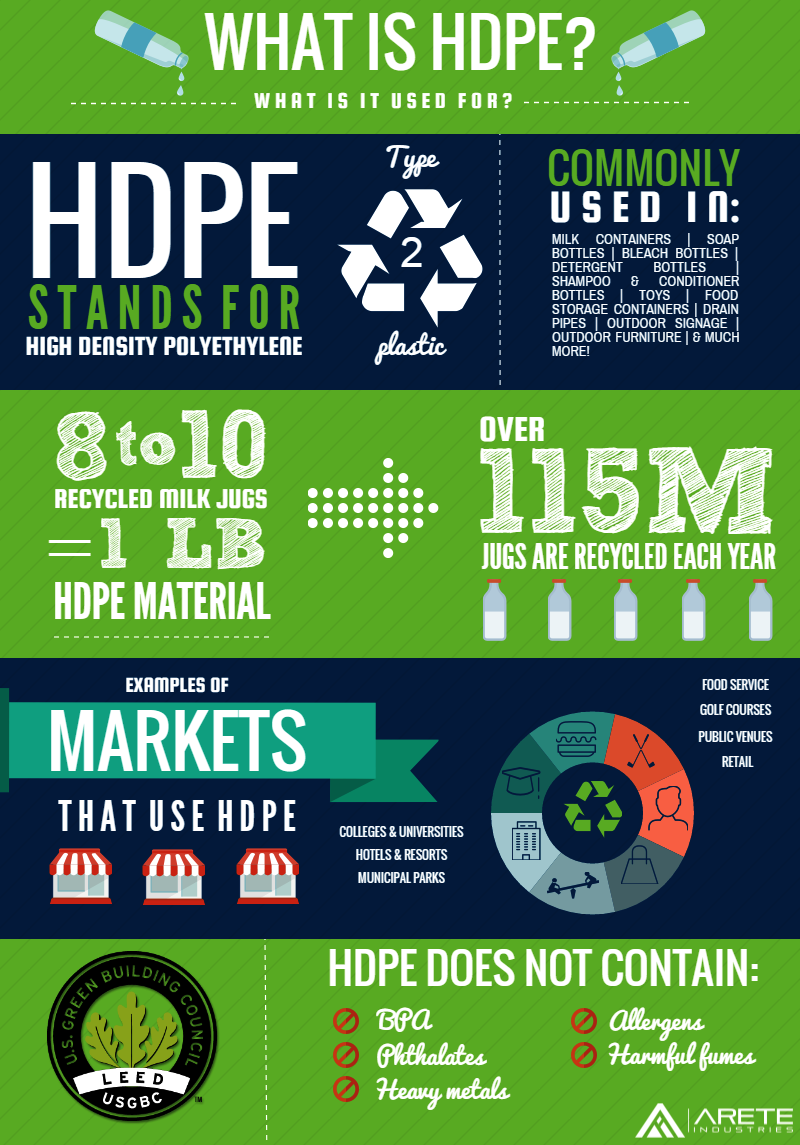

- HDPE is an acronym for High Density Polyethylene

- High Density Polyethylene is a polyethylene thermoplastic made from petroleum. HDPE is commonly recycled and made into composite wood or plastic lumber

- HDPE is a Type 2 plastic commonly used in making containers for milk, motor oil, shampoos and conditioners, soap bottles, detergents, and bleaches.

- HDPE is known for its large strength-to-density (maximum stress a material can withstand)

- Products made from Type 2 HDPE recycled plastic are considered Eco-friendly because they are made mainly from post-consumer products and are recyclable at the end of their useful life.

- Generally post-consumer products used in making HDPE include bottles such as milk and detergent bottles. Approximately 8-10 recycled milk jugs make up a pound of HDPE material.

- Over 115 million milk jugs are recycled each year in the making of HDPE recycled plastic.

- HDPE Does not contain BPA, phthalates, heavy metals or allergens.

- HDPE plastic is the most environmentally stable of all plastics – giving off no harmful fumes into the environment.

- Manufacturing HDPE plastics requires only a fraction of the energy required to produce steel from iron ore, further contributing to its classification of being Eco-friendly.

- HDPE recycled plastic is essentially maintenance free, with exceptional resistance to salt spray, oil, moisture, fading, insects, graffiti, splinting, warping and other hazards of environmental exposure common to wood or wood fiber composite products.

- Healthy Building recommends HDPE resin based products as the most environmentally friendly building material.

- HDPE is commonly used to make toys, food storage containers, marine products, drain pipe, food preparation products and outdoor signage.

- When HDPE is recycled it is available in both profile lumber and sheet form, allowing for many popular outdoor products such as waste & recycling receptacles, decking, bike racks, benches, picnic tables, fencing and furniture.

- HDPE products are used in many markets settings including hotels and resorts, colleges & universities, food service, retail, golf courses, municipal parks and public venues.

- Use of HDPE materials contributes towards satisfying LEED credits.